Tipton, West Midlands — Bodill Parker, one of Britain’s longest‑established manufacturers of precision‑engineered eyelets and metal components, today announces a strengthened end‑to‑end service that integrates product development, tooling, manufacturing and full in‑house assembly. This enhanced capability enables customers to benefit from a single UK source for both components and finished, assembled products across sectors including defence, camping and outdoor equipment, premium stationery, branded gift tags and more.

With more than 165 years of manufacturing heritage, Bodill Parker’s product development process blends deep engineering experience with modern precision standards. The company works collaboratively with customers from concept through to production, conducting in‑house trials to perfect performance, longevity and ease of assembly before any product goes to market.

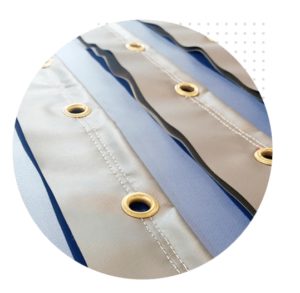

Bodill Parker’s expanded assembly capabilities directly benefit manufacturers using technical webbing in military, marine, industrial and outdoor applications. British‑made brass and stainless‑steel eyelets—alongside thimbles, hooks and tent hardware—are already used widely in tents, sails, marquees and marine rigging, making the company’s vertically integrated service ideal for reinforcing straps, harnesses, tactical gear and heavy‑duty textile interfaces where reliability is critical.

By providing both components and full assembly under one roof, Bodill Parker helps customers reduce handling, improve consistency and shorten lead times—all with the assurance of British and European manufacturing standards.

Beyond industrial sectors,

Bodill Parker now supports the booming market for eyelet‑enhanced stationery, offering precision‑set metal fasteners for:

Layered or vellum‑overlay wedding invitations

Luxury gift cards and branded retail tags

Decorative menus, place cards and event stationery

Market demand for eyelet‑finished paper goods continues to grow, with UK suppliers offering reinforced eyelet tags and designers popularising metal‑fastened invitation styles. By assembling these elements in‑house, Bodill Parker delivers clean, consistent results that elevate presentation and durability.

Beyond industrial sectors,

Bodill Parker now supports the booming market for eyelet‑enhanced stationery, offering precision‑set metal fasteners for:

Layered or vellum‑overlay wedding invitations

Luxury gift cards and branded retail tags

Decorative menus, place cards and event stationery

Market demand for eyelet‑finished paper goods continues to grow, with UK suppliers offering reinforced eyelet tags and designers popularising metal‑fastened invitation styles. By assembling these elements in‑house, Bodill Parker delivers clean, consistent results that elevate presentation and durability.

A standout differentiator for Bodill Parker is its ability to serve as a single‑source subcontract manufacturer. Assembly services are ideal for customers who want ready‑to‑use components incorporated directly into their products—removing the need for secondary processing, reducing error rates and consolidating their supply chain.

The company’s comprehensive capabilities include:

- Manufacturing eyelets, grommets, rings and thimbles to BS 3102 and BS 3226 standards

- Producing bespoke metal pressings for defence, marine, aerospace and automotive industries

- Offering tooling solutions and machine‑ready setups for hand, foot, toggle or electric presses

- Delivering fully assembled components with quality control built into every step

These advantages align with best‑practice principles in contract assembly—improving repeatability, reducing costs and streamlining production flows for OEMs.

A Trusted British Partner for Precision, Flexibility and Quality

All Bodill Parker products are manufactured at its Tipton facility in the Black Country, ensuring complete oversight of materials, craftsmanship and quality standards. With the ability to accommodate small bespoke runs and high‑volume production alike, the company remains committed to responsive lead times and engineering‑led support at every stage.